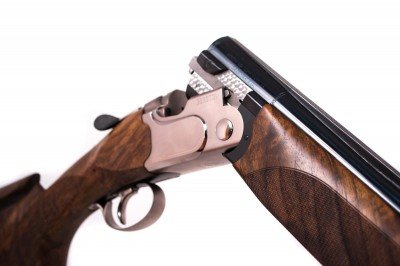

The Beretta 692 Sporting with B-Fast Adjustable comb.

On this, the 3rd day of October 1526. [To] Master Bartolomeo Beretta of the Brescian territory of Gardone for 185 arquebus barrels [made] for Our House of the Arsenal [given] 296 ducati.

So begins the history of the world’s oldest gun maker – Beretta. By the way, in 1526, 296 ducati was a lot of Benjamins. While it’s pretty hard to make an inflation-adjusted comparison, we know that Leonardo Da Vinci’s apprentices were paid 1/10th of a ducat per day, about 36 ducats a year, so Beretta’s first order for gun parts was about eight years pay for a hard working artist-inventor-mason-painter worker. We also know that Leonardo had about 600 ducats in his checking account in 1499, so if Beretta had been founded a few years earlier, he could have paid cash for 185 arquebus barrels, leaving plenty in the bank for a healthy ammo stockpile.

Italy’s Trompia Valley, home of Gardone, is flush with the right materials for gun making. Iron ore deposits abound and heavy forests provided the wood to stoke smelteries and smithies. Back in the day, barrel making was a bit different. Craftsmen pounded iron plates around a mandrel, overlapping them along a longitudinal seam. By mashing the snot out of the joints, they created solid barrel blanks, which were then shaped to final dimensions.

While early history of Beretta shows an emphasis on military arms, it was Guiseppe Beretta who stepped on the gas to ramp up production of sporting arms. In the 1850s, only 250 to 300 guns were produced annually. By the 1880s, that number exploded to almost 8,000 per annum.

Many early shotguns featured side by side barrel configuration, mainly because it was easier to produce a strong locking mechanism and figure out how to “light” each barrel. By the 1930s, engineers finally got really comfortable with good sidekick designs and over / under shotguns took off. One Beretta story relates company inventor, Tullio Marengoni, demonstrating the strength of his new over / under cross bolt lock to the Berettas by securing the barrel and receiver to the stock with rope – and firing the gun himself. The gun held together, and the design was adopted.

Enter one of the latest Italian shotguns – the Beretta 692 Sporting. Since we’re talking Italian here, we’ll describe it as a “Sovrapposto” meaning over and under barrel configuration.

The newest iteration of the 692 Sporting line fills a gap in the Beretta product line for trap shooters wanting a high-quality gun without spending in the five digit range. At the top end is the DT-11 family – fantastic shotguns and the choice of plenty of Olympian shooters. But the DT-11 comes at a price point out of reach of many non-sponsored shooters. Moving into the two to five thousand price range, there was not a new production gun optimized for trap until now. The 692 Sporting line has been out for a while, but not with an adjustable comb and long barrels. It’s been the same with the recent Silver Pigeon line – fantastic guns for sporting clays and skeet, but none optimized for the trap field. Semi-automatics like the 391 series have been a viable option, but many shooters prefer the feel and convenience of break action shotguns for trap sports.

This particular 692 Sporting model is not off the press – literally. Our sample gun, shown here, is the first one of its type to hit US shores. It’s got the B-Fast comb system for near-infinite adjustment and extra long barrels (32-inch) preferred by many trap shooters. Just to be clear, this is not a dedicated trap gun – it’s well suited for skeet and sporting clays. It just offers features that make it suitable for trap as well.

Let’s take a closer look.

Barrels

Borrowing from that high-end DT-11 line we mentioned earlier, the 692 Sporting model also uses “Steelium” barrel technology. Steelium is a fancy marketing name that, quite frankly, sounds a little goofy to me, but that’s neither here nor there. Here’s what it means.

Now producing over 500,000 gun barrels of various types each year, Beretta knows a thing or two about how to optimize a shotgun barrel. The biggest deal on this one, outside of uniformity, longevity and over/under alignment, is the forcing cone. That’s the conical section at the breach end that helps gently transition the shot load into the standard barrel diameter. By making this transition more gradual, you get a couple of benefits. First, the shot doesn’t get as mashed up. Lead pellets tend to stay round and uniform, and as a result, fly in a tighter and more consistent pattern. Second, the “shock” of the pellets leaving the shell and forcing their way into the muzzle is mellowed and drawn out over a longer period of time. While the overall recoil energy is still the same, the impact of the shooter is smoother and more spread out. This not only helps improve felt recoil, but also muzzle rise, encouraging a faster transition to a second shot.

To put the forcing cone improvements into mathematical perspective, a standard forcing cone has an overall length of about 65 millimeters. The Steelium PRO cone is a whopping 360 millimeters in length. That’s quite a difference that contributes to the gentle shooting and excellent patterns.

The chambers are cut for 3-inch shells should you want to hunt with your 692 Sporting. While we’re talking about chambers, the ejection system is adjustable with included tools.

The 692 Sporting features a wide rib that tapers in towards to the muzzle. I measured the rib just forward of the receiver at .39 inches wide. At the front bead, the rib narrows to .318 inches. A single white bead is mounted at the muzzle and there is no center bead or hole for one. This is fine with me as too much stuff on the rib is a distraction that pulls attention away from the target and back to the beads.

Read the rest at GunsAmerica!

Be sure to check out our latest books! They are ON SALE now for a limited time!

Beautiful gun.. I wish I had one..