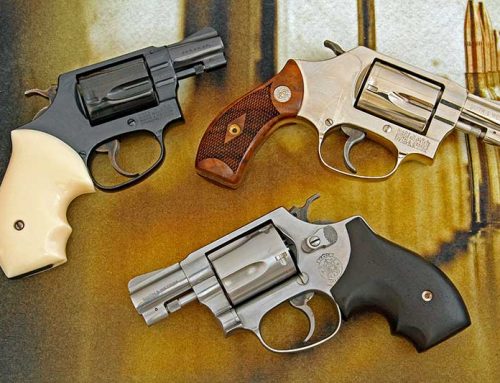

The new ATI TactLite AR stocks. The standard model is on the left and adjustable comb model on the right.

You might have noticed that most adjustable butt stocks for AR-type rifles shake just a little. Worse yet, the farther you move that adjustable stock back, the more the shake. We’ve probably learned just to accept it, kind of like that “sproing” sound that many ARs used to make when fired.

While the movement of the stock on the buffer tube is not a desired design feature, there’s actually a reason it happens. Here’s why. Most stock pieces are made of polymer (plastic of some sort) and are manufactured using injection molding. You slather a bunch of melted plastic glue into a mold. Then, when it hardens, you remove the finished part from the mold. When you’re making a mold that’s intended to fit around a perfect cylinder shape, like a buffer tube, you can’t make the part an exact mirror image of that cylinder, else it will get stuck in the mold. To solve that problem, most manufacturers make the interior of their butt stocks slightly tapered. The innermost portion is the proper dimension for the buffer tube, but the cavity gets a bit larger as you move towards the opening at the front of the stock. Voila! The cavity is a bit larger than it needs to be, hence the shake.

I talked to G. Schneider, Lead Engineer at SHOT Show and asked him why ATI set about inventing a new stock design. “We heard customers complain about the shake with existing stocks. We didn’t want to design a stock with multiple parts to solve that problem – we wanted a single piece unit that was in the six ounce weight range.”

Got something to say?