The Sig Sauer Ammunition folks have been somewhat busy the past couple of years. Entering the ammo business a couple of years ago, they started with a few assorted pistol calibers. Now, they offer dozens of loadings including .223, .308, 300 Win Mag, and yes, 300 AAC Blackout. Heck, they’re even making revolver ammo like .38 Special, .357 Magnum, .44 Special, .44 Magnum and even .45 Colt. I don’t recall seeing too many Sig Sauer .45 Colt revolvers at my local range, so apparently the ammo team isn’t limiting themselves to Sig guns.

We tested the Sig Sauer 300 Blackout Subsonic ammo a while back, so we figured it was time to report on the 300 Blackout 125-grain Supersonic load. Sig also makes an expanding 120-grain hunting round called the HT, but we’ll cover that in a future story.

The supersonic load is match grade and is tipped with a 125-grain Sierra Matchking projectile. Technically, like most Sierra Matchking rifle bullets, it’s a hollow point, or more accurately, Open Tip. However, that’s more of a manufacturing convenience and accuracy aid, and it’s not intended to expand, nor will it. These bullets are meant to fly straight and stay together.

I shot a goodly supply of this ammo through a Daniel Defense DDM4v5 300 Blackout rifle. It’s got a 16-inch barrel and has proven itself to be an accurate shooter, so I figured it would give me a decent indication of the consistency of the Sig Supersonic Blackout load. I did all the shooting with a Silencerco / SWR Specwar 762 suppressor, because, why not?

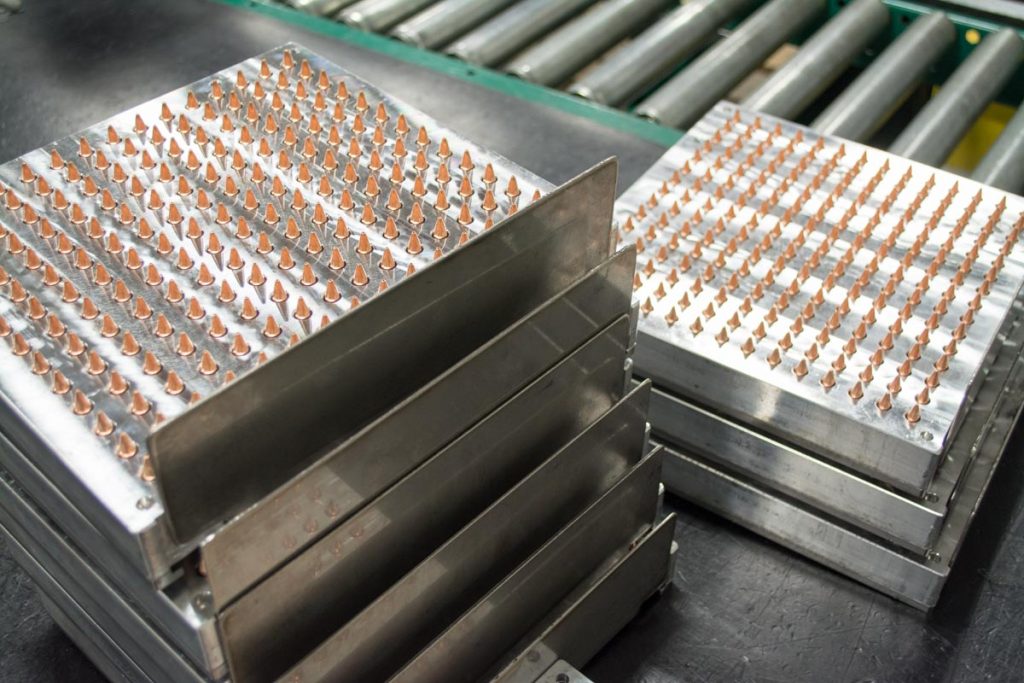

Sig loads the 300 Blackout using trays of 210 at once to get better batch consistency.

I toured the Sig ammo factory in Eubank, Kentucky last year and saw first-hand how finicky those people are about consistency. Sig loads ammo using a tray system, so 210 rounds are processed at once for each step of the loading process. They’ve designed and built all sorts of consistency and quality checking technology into their process that makes use of laser, optics, scales and human eyeballs to check and verify every dimension and weight throughout the process. Where that attention to detail should become apparent is on the range, so I did some velocity and accuracy testing.

Got something to say?